Throughout its history, Meriaura Group has sought to find alternatives to fossil fuels for developing shipping more sustainable. We did our first bio-oil experiment already in 1992 with the tugboat ‘Aura’.

We have verified the usability of 100% biofuel made from recycled raw materials in shipping through long-term tests and with regular use in our own fleet. The work continues with the development of fuel certification and quality standardization.

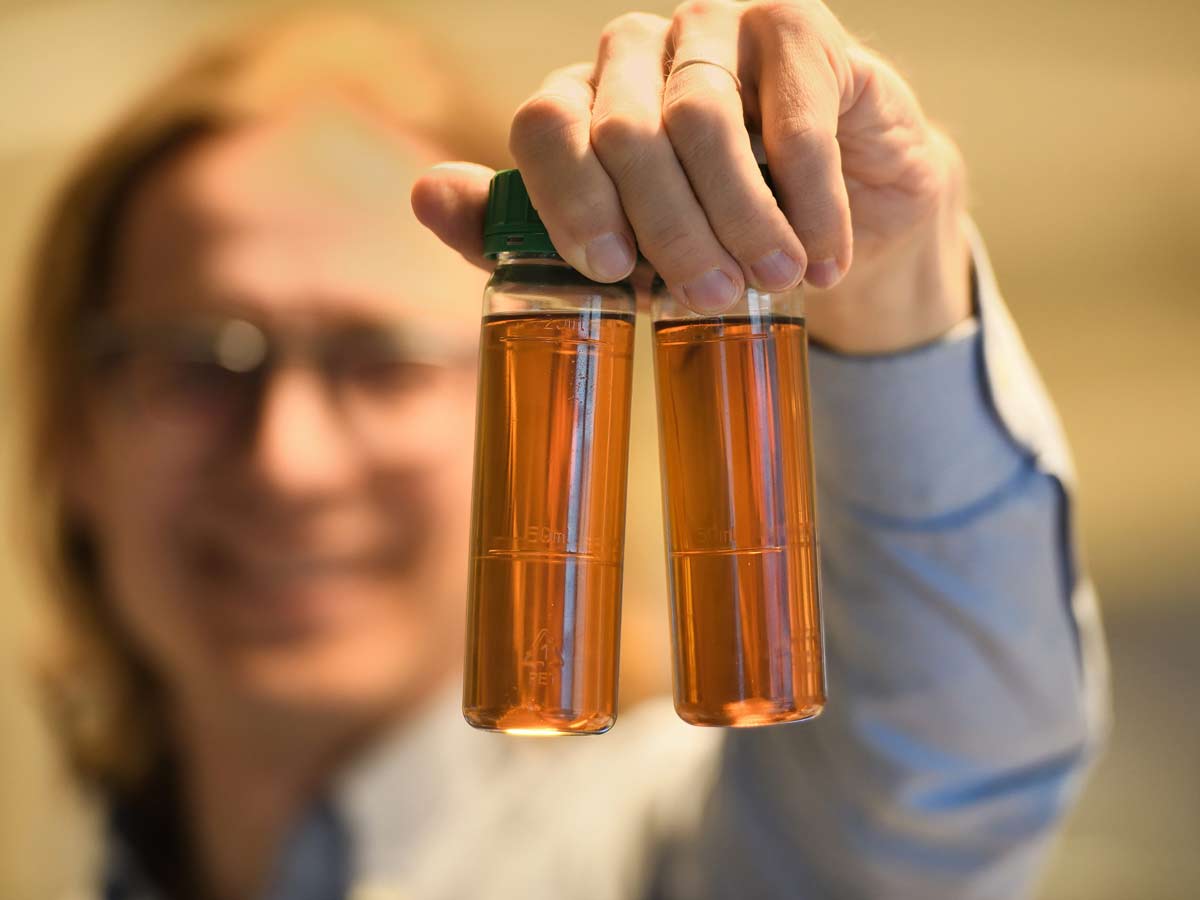

The bio-oil we use is manufactured by VG EcoFuel Ltd. (a member of Meriaura Group) from recycled oils and by-products of the food industry. Therefore the oil production does not compete against land for agriculture. Waste-based bio-oil is therefore ethically sustainable, and its use reduces ship’s CO2 emissions by up to 97,7% compared to the traditional fossil fuel option. Thanks to the catalyzers nitrogen emissions are also close to zero. Waste-based bio-oil is the most sustainable fuel solution currently available in maritime transport.